Innovation is no longer a choice in the construction industry; it’s a must. 3D BIM drafting is one of the most important new technologies that is changing how structural steel projects are planned, built, and carried out. BIM, which stands for Building Information Modelling, is an intelligent model that combines design, data, and collaboration into one. It is the digital backbone of a construction project.

3D BIM drafting has changed how engineers, architects, and fabricators work together on everything from skyscrapers to factories and bridges. It replaces old-fashioned 2D blueprints with 3D models that are dynamic and full of data that show how things really are in the world. This helps teams make fewer mistakes, save money, and finish projects faster.

Moving from 2D to 3D modelling

Structural steel detailing has always used 2D CAD draftings, which are flat representations of complicated structures that often led to misunderstandings and costly mistakes during fabrication or installation. But with 3D BIM modelling, you can see every beam, connection, and joint in a virtual space before any real work starts.

Engineers and designers can now find potential clashes early, see connections clearly, and make sure everything fits perfectly in the field thanks to the switch to 3D steel modelling. It helps steel detailers, architects, and MEP engineers work together better, which cuts down on rework and delays on the job site.

Exactness and Precision

In structural steel projects, accuracy is key. A small mistake in the size or connections can cause delays, safety problems, or money loss. 3D BIM drafting gets rid of these risks by making a smart model that has information about material specifications, load calculations, and connection details built into it.

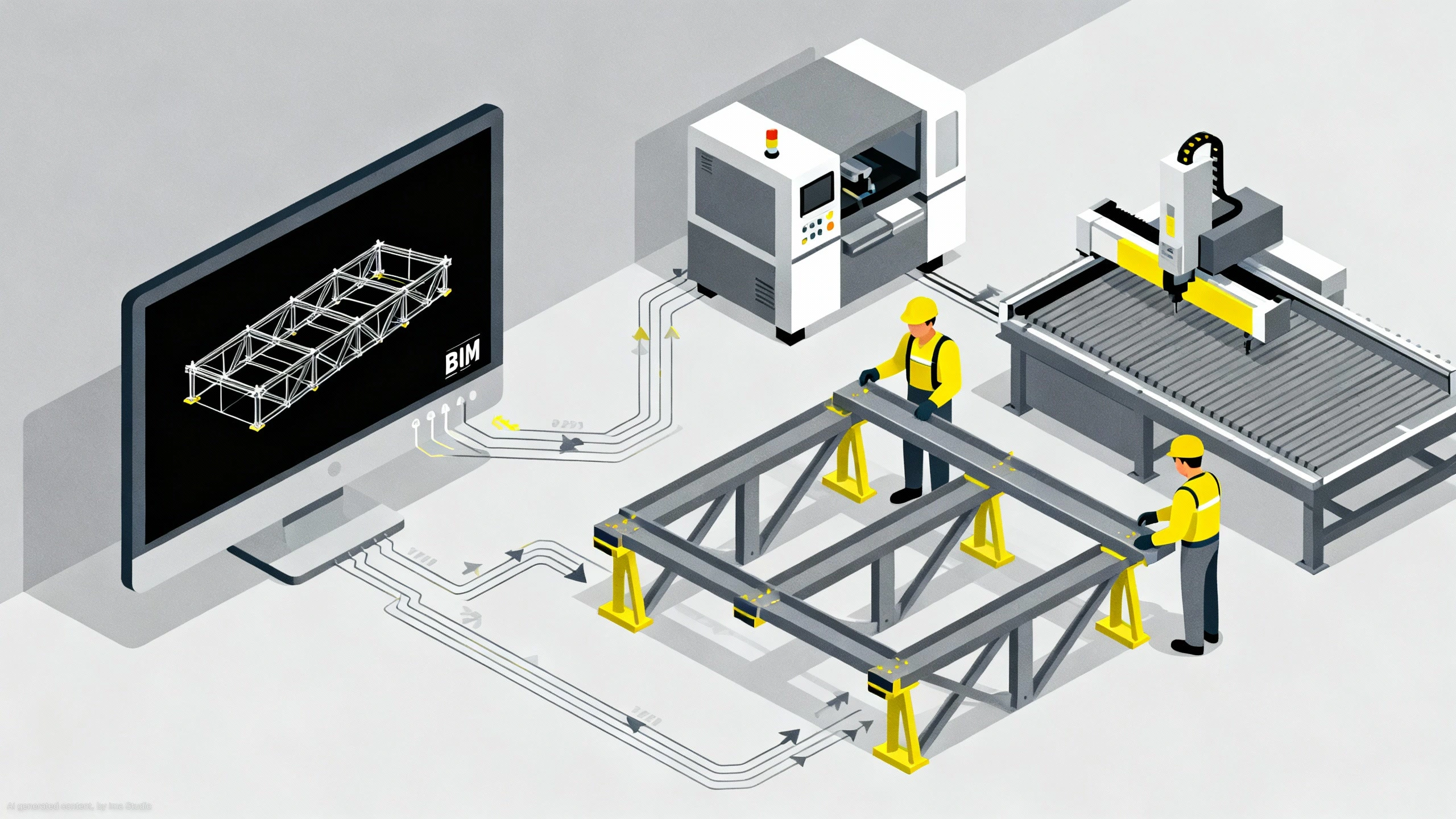

BIM helps make sure that every part of a steel structure is made exactly how the model says it should be. CNC integration can also connect the model directly to fabrication machines, which speeds up the production of steel members and reduces the chance of human error. Using regular 2D draftings, it’s almost impossible to get this level of accuracy.

Better teamwork between teams

BIM drafting for structural steel has another big benefit: it makes it easier for people to work together. There are usually several teams working on different parts of the same construction project. These teams include designers, structural engineers, contractors, and fabricators. Everyone involved in a project can see the same central model with BIM, which makes sure that everyone gets real-time updates and can talk to each other easily.

This way of working together keeps misunderstandings from costing a lot of money. When an architect changes the size of a column or the level of a floor, the change is instantly shown in the BIM model, which tells the steel detailer or engineer to make the necessary changes. This real-time coordination keeps everyone on the same page and cuts down on delays in the project.

Efficiency in terms of cost and time

It may seem like a lot of money up front to use 3D BIM drafting services, but the benefits over time are much greater than the cost. The model-based process cuts down on mistakes, waste, and the time it takes to make and install things.

By finding problems before building starts, teams can avoid costly changes and rework on the site. Studies in the industry show that using BIM in steel construction can cut project costs by up to 20% and make projects go much faster. These savings are game-changing for big steel projects in business or industry.

Better planning and seeing things clearly

With 3D BIM modelling, everyone involved can see what the whole building will look like before it is built. This is especially helpful for clients and project managers who might not be able to understand regular 2D technical draftings. BIM models are easier to see, which helps people make better decisions and get approvals faster.

BIM also lets teams plan every step of steel erection in a virtual environment by allowing construction sequencing and simulation. This helps find problems with logistics, make the site safer, and make the best use of cranes and other tools.

Working together with Fabrication and Construction

One of the best things about 3D BIM for steel structures is that it can work directly with the processes of making and building things. You can send the model data to fabrication software or CNC machines, which makes it easy to go from digital design to real-world production.

This process of going from a model to a finished product makes sure that every piece of steel is cut, drilled, and welded perfectly. It makes people less dependent, speeds up production, and makes the quality of construction better overall. Because of this, BIM-driven steel fabrication is becoming the new standard in the business world.

Managing the lifecycle and being environmentally friendly

Sustainability is becoming more important in construction, and BIM drafting is a big part of that. It helps building practices that are good for the environment by making the best use of materials and cutting down on waste. BIM models are also digital twins that can be used for maintenance, renovation, and facility management throughout the building’s life.

A single digital record that holds all the information, from material grades to assembly sequences, makes it easy to make changes or add on in the future with little trouble. This means that BIM for structural steel projects is more than just a design tool; it’s also a way to manage assets over time.

Steel Construction in the Future

3D BIM drafting will only get smarter and more connected as technology keeps getting better. BIM, AI, and automation will work together to make predictive modelling, cost estimation, and real-time progress tracking even more accurate. The days of draftings that don’t connect and teams that don’t work together are over. The future is in BIM-powered steel construction that is based on data.

FAQs

- What does 3D BIM drafting mean for structural steel projects?

Using Building Information Modelling software, 3D BIM drafting makes detailed, data-rich 3D models of structural steel frameworks. It helps you see, plan, and keep track of every step of design and construction with great accuracy.

- How does BIM help steel projects make fewer mistakes?

BIM lets everyone involved work on the same digital model, which makes it easier to find design problems and inconsistencies early on. This reduces the amount of work that needs to be done again, the amount of materials that are wasted, and the number of mistakes made on site.

- Is it okay to use BIM drafting for small steel projects?

Yes, BIM modelling is good for projects of all sizes. For smaller projects, it makes sure that the work is done more accurately, more quickly, and with better coordination.

- What software do people usually use to draft BIM steel?

Tekla Structures, Revit, Advance Steel, and AutoCAD Plant 3D are all popular programs that let you model and detail steel in 3D with data that is ready for fabrication.

- What are the main benefits of using 3D BIM drafting?

Some of the main benefits are better accuracy, faster project delivery, better collaboration, lower costs, better visualisation, and compatibility with fabrication and construction processes.